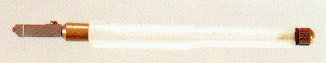

Buying the right tools Buying the right tools for your hobby is important if you want to do a good job. Starter glasscutter..

NZ.$ 4.80 plus G.S.t

cheap glasscutter can be found in most hardware stores for under $6,

however is useless if you want to work in stained glass.It's cutting

wheel blunts quickly and easily and can cost you much more, if you

waste a lot of glass, because it wont cut properly. good oil glasscutter.

NZ.$ 32.50 plus G,S.T

The preferred glasscutter for stained glass is (above) an oil-cutter,

it is slightly dearer to buy, but will save you money on the glass

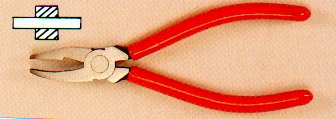

as it is easier to cut with and it will last you a much longer time. Glass pliers.

NZ.$ 15.50 plus G.S.T

Don't just get a pair of pliers out of the tool box, chances are they

will chip and break the glass.A pair of grozing pliers are (above )cheap and

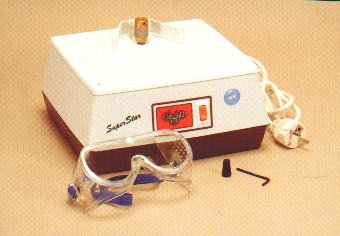

have the proper mouth opening as needed for breaking glass. Glass grinder..

NZ.$ 195.00 plus G.S.T handling free in NZ.

You will need to invest in a grinding machine, (above)the grinder

which fills with water and has a diamond grinding head is in my opinion

a good buy and with proper care will last you for years. 80 Watt "Weller" Soldering iron..

NZ.$ 78.50 plus G.S.T

You will need an 80 watt "Weller" soldering iron,(above) which are very good

quality soldering irons.Again in most hardware stores you may find

copper tip soldering irons which are no good, they wear down quickly

and don't do as good a job. All the tools illustrated are the ones we use and have done so from

the beginning.In our opinion, they are the best tools for stained

glass.They are good quality tools which will last you for years,provided

of cause you look after them properly.

Please read on for easy care instructions The Glasscutter: Your glasscutter has a screw top undo this to pour in some fine machinery

oil, when pressure is applied during cutting the oil will flow forward

lubricating the little diamond wheel of the glasscutters head.However this also leaves a

film of oil on your glass which has to be wiped off before you can

apply the copper foil, otherwise this will effect the stickyness of

the foil.Another alternative is to leave the glasscutter standing

in a glass with a bit of machinery oil in when you're not using it

and just wipe the oil off before you start to cut.Also don't let other people use your glasscutter as everyone has a

different way of how they hold and guide it.Avoid dropping it onto

the floor and when cutting avoid damaging the edges of the glass.

2.The Grinder : Don't forget to fill your grinder with water and to use the sponge

to moisten the grinding head.

If you're not using the grinder for a longer period of time, empty

the water.Also don't move the grinder from one place to another when

there is water in.

Residue buildup from grinding has to be removed every so often, a

flat spatula can be used to slide over the bottom.

3. The Soldering iron : Turn off the soldering iron when during your work you have to do something

else, even if it is just to fix a sandwich.

When you have finished using the soldering iron for the day let it

cool off, then undo the little screw which holds the solder irons

tip and remove the tip.If you don't do this the tip will eventually

burn itself into the soldering iron and wont be able to be removed

when you want to replace it.

Don't use anything harsh on your soldering iron like sandpaper to

get rid of the gung buildup on the tip.When the soldering iron is

hot use a cloth to quickly wipe it off or take a quick dip into the

flux.

Remember when your tools do get worn down there are replacement parts

available, which are cheaper than buying a brand new tool.For example

on the grinder the grinding head gets the most wear, it can be adjusted

to a higher or lower setting or turned over so that you can use almost

every angle on the head.The same with the soldering iron, the tip

usually wears down first and that can also be replaced with a new

one. 1 go to.. CLASSES-Chapter-1 problem..... Contact Us Features 2 |